The #ProFuture research consortium has pioneered an indirect solar drying method-as an alternative to freeze-drying (or freeze-drying)-to obtain microalgae that are sustainable in both environmental and economic respects. (1)

Foreword. ProFuture, research and innovation for microalgae

The ProFuture project, funded in the Horizon 2020 program, is dedicated to research and innovation on the use in food and feed of four microalgae species:

- Arthrospira platensis(aka spirulina),

- Chlorella vulgaris (Chlorella),

- Tetraselmis chuii,

- Nannochloropsis oceanica. (2)

Some scientific papers-already published and available on the ProFuture website, along with other updates on microalgae-are about:

- Addition of microalgae in plant creams, (3)

- Market analysis of microalgae products in Spain, Europe, world. (4)

1) Solar drying of microalgae, the study

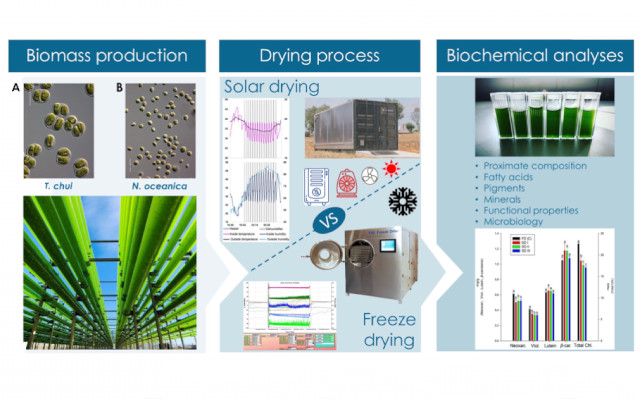

The latest study published by ProFuture researchers (Schmid et al., 2022) explores the possibility of drying microalgae through solar-drying, including from an industrial perspective.

Microalgae Tetraselmis chuii and Nannochloropsis were therefore subjected to solar drying, compared with freeze-drying (a widespread, but expensive and energy-intensive food technology).

2) Indirect and hybrid solar drying

Solar drying is a technology of strong interest because of its energy efficiency-which results in significant savings in production costs-and its potential for use in rural settings. It is in fact widely used in tropical countries where constant high temperatures can be relied on. Some limitations include the possibility of its efficient use in countries with lower availability of constant solar radiation throughout the year, as well as the design of the plants. (5)

The need to safeguard product quality led researchers to experiment with indirect solar drying, thus without exposing the microalgae to direct solar radiation. Also in a hybrid version–in combination with a fan heater, dehumidifier and ventilation system–for the purpose of:

- Supplement indirect radiation as needed,

- control and maintain process environmental parameters (temperature and humidity primarily) in the normal range, at a relatively low cost.

3) Quality of microalgae

The characteristics analyzed on microalgae dried by the different methods pertain to their composition, technological functionality and microbiological paramenters. The results obtained by indirect and hybrid solar drying are quite satisfactory, noting no significant differences with those resulting from freeze-drying. A summary of the specific values considered in the study follows.

3.1) Composition

Humidity. Relative humidity values obtained with solar-drying were higher, compared with much faster (28 hours with indirect solar-drying, 60 in freeze-drying).

Proximal composition. Protein, lipids and carbohydrates are almost unchanged. So do saturated, unsaturated and polyunsaturated fatty acids, which are thus found to be insensitive to oxidation (EPA, in particular).

Pigments. A different situation occurred between carotenes and xanthophylls. β-Carotene and lutein did not vary significantly, while violaxanthin, neoxanthin and zeaxanthin were much lower. The same reduction was observed in total chlorophylls.

Minerals. Few differences were found among the minerals. Sodium remains present in high levels, in the two microalgae species, and any pretreatment can be reduced to acceptable levels.

3.2) Microorganisms and technological properties

Microorganisms. Microalgae subjected to solar drying had higher total PCA counts and xerophilic molds were detected (albeit in low concentration, < 102 CFU/g), probably due to the higher process temperatures. Both products are evaluated as meeting food safety requirements, based on guidelines provided by Belgium’s Ghent University for these parameters No traces of the fecal contamination indicator Escherichia coli were found instead. (6)

Technological properties. Emulsifying and foaming abilities were lower in microalgae subjected to solar drying. These effects are not attributed to the technology (since high temperatures generally promote both of the aforementioned properties), but rather to the composition of the two microalgae used Tetraselmis chuii and Nannochloropsis and changes in their surface structure.

4) Interim Conclusions

Comparison of microalgae subjected to indirect solar drying and freeze-drying in the cases under study showed several quality aspects in favor of freeze-drying. However, the results obtained with solar drying are promising, and it is useful to note how solar drying has already enabled food grade products.

However, research is still in its infancy, and areas for improvement are already being glimpsed in order to increase process efficiency and obtain products as close as possible to those obtained by freeze-drying and other similar technologies. Therefore, it seems appropriate to pursue the development of a technology that is sustainable, cost-effective and replicable even in contexts almost devoid of technological facilities.

Dario Dongo and Andrea Adelmo Della Penna

Cover image from Schmid et al. (2022)

Notes

(1) Schmid et al. (2022). Drying Microalgae Using an Industrial Solar Dryer: A Biomass Quality Assessment. Foods 11:1873,

(2) Dario Dongo. ProFuture, microalgae to feed the planet. The EU research project. GIFT (Great Italian Food Trade). 18.6.19

(3) Dario Dongo and Andrea Adelmo Della Penna. Adding microalgae to vegetable creams, ProFuture. GIFT (Great Italian Food Trade). 3.11.21

(4) Dario Dongo and Andrea Adelmo Della Penna. Alt Yogurt and Alt Cheese, market and criticality. ProFuture research. GIFT (Great Italian Food Trade). 28.12.21

(5) Mohana et al. (2020). Solar dryers for food applications: Concepts, designs, and recent advances. Solar Energy 208:321-344.

(6) Uyttendaele et al. (2018). Microbiological Guidelines -Support for Interpretation of Microbiological Test Results of Foods. Die Keure Publishing.